Not long ago, Bloomberg Businessweek put out a great exploratory piece into the complicated and confusing industry of floor safety, design, and standards. What the author and reporter were able to highlight was the decades of challenges the industry has faced to set in place acceptable standards to ensure overall safety. Being in the trenches of the industry myself over the years, I have come to know the players involved and the growing pressures between committees fighting to define the best standards possible. Unfortunately, vilification of manufacturers is common, but in the circumstances explored in Bloomberg Businessweek’s article and video, the vilification of the organizations involved in standards development of slip testing is not accurate. In fact, the research and development relied upon by organizations like the Tile Council of North America have not only been the most successful and gained the most consensus in the industry but is also based on reliable independent research that has been adopted by many countries and only recently brought to the US.

Colleague Peter Ermish, the owner of Walkway Management Group, says, “This is not our standard or the TCNA’s, it’s that of the rest of the world, EU standard recognized by 27 countries. We were aware of the research in Europe and introduced TCNA to that research.” Ermish brought the technology used overseas to the US and created the BOT-3000 and eventually developed the updated BOT-3000E tribometer which is now the industry standard for testing floors. And he is correct, the standard referenced in the video, the ANSI A326.3, is based on the research and standards that were already in place and used overseas.

Russ Kendzior, who was really the highlight of the piece, is portrayed as the hero of the industry, even claiming to have inadvertently changed the world, a role he has long declared and enjoyed. The author even describes Kendzior’s drive as “Kendzior sees this as a crusade, standing up to big floor.” Kendzior’s organization, the National Floor Safety Institute, once an ANSI Standards Developing organization, publishes its own standards for slip resistance testing that are purported to oppose the standard published by the TCNA.

The Bloomberg piece leaves out a significant detail between the two men interviewed and their differing views, and seemingly competing standards – They’re both based on the same research and international consensus. The disagreement between Kendzior and the rest of the industry is not a technical one, but an opposition based on credit and control. Kendzior, he’s the hero, and everyone else is just not cool enough.

Understanding the Industry Standards at Work

The American National Standards Institute’s (ANSI) goal is to “provide a neutral forum for coordination and identification of standards and conformity assessment needs in support of emerging technologies and national/global priorities.” ANSI doesn’t just focus on the floor industry, but has collaboratives involving multiple U.S. sectors and developers, including infrastructure, healthcare, nanotechnology, sustainability, and even the commercial space industry as of 2020. These innovations and standards developments were made possible thanks to the creation of committees allowing for multiple stakeholders from all areas. In an effort for transparency, meeting notes and summaries are made available to the public, thereby making the findings and conclusions readily accessible to those who need them as well as allowing for further discussion and cross-examination. The fact that ANSI has a hand in multiple industry areas indicates that there is no one specific agenda at play, but rather a goal to develop industry consensus standards in fairness. While the independent groups may be experts in their own rights, it is important to acknowledge that the benefit of organizations like ANSI is that their committee process requires committee review and consensus and specifically prohibits dominance by one person or group to ensure that no one agenda rises above the other.

ANSI A108, the committee run by the TCNA, has been an ANSI SDO approximately since 2005 and has long provided standards development for the tile and stone industry, not just for slip resistance but every aspect of these flooring types from materials and manufacturing to installation. Despite Kendzior’s assertion that ANSI A108 or TCNA is “…corporate America on Steroids,” in actuality the committee is required, by ANSI rules, to include a variety of professionals. Under requirements for a Company Member on their website, ANSI looks for, “A corporation, partnership or other entity that is created under the laws of the United States or any state, district or territory thereof and that is engaged in industrial or commercial enterprise or professional, educational, research, testing or trade activity. Any affiliate, division or joint venture of a corporation, company, firm or partnership may, at the discretion of the ANSI Executive Committee of the Board of Directors, be eligible for membership.”

Similar to ANSI, what was the American Society for Testing and Materials, and is now ASTM International, is a standards developing organization focused on public health and safety. The organization utilizes technical experts from around the world and welcomes a collaborative environment that meets the needs and expectations of participants. As one of their five objectives, ASTM International states to “always be relevant and continuously enhance the technical quality of standards and related content by providing a best-in-class, scalable development infrastructure.” Like ANSI, ASTM International has hundreds of committees focused on developing standards in their area of expertise. From pedestrian and walkway safety (F13) to stormwater control measures (E64), and even, nonferrous metals and alloys (B02), committees welcome members dedicated to developing standards. Membership is even free for students as having clear transparency of standards will give them a leg up as they become industry professionals. The collaborative insight from students will only contribute to the multitude of benefits the industries can gain.

The International Organization for Standardization (ISO) is another international standards developer which provides similar transparency and public review of the standards developed and is open to multiple groups. The point of these organizations and committees is to create a cross section of varied experience areas and stakeholders who all have unique input into the industry. That doesn’t mean each committee won’t have disagreements with individual priorities coming into play, but the fact that so many people with varied experiences are involved allows for a thorough examination and development to eventually reach a point of industry wide accepted consensus.

The value of these organizations is that they do not have any skin in the game. They have almost no scientific or technical oversight in the committee, but they make sure that a strict consensus process is followed and that committees are not dominated by one person or group. It’s important to note that the self-proclaimed “hero” of the industry’s organization isn’t an ANSI developer anymore. The merit of these committees is that they work under an authority that prevents dominance. As pointed out by the author, when “you are convincing you tend to make a lot of enemies.” When you dominate a standards committee, you also make a lot of enemies, and now there is an ex-ANSI standards developer trying to call the shots. (*This article represents my opinion based on my own experiences and facts and draws conclusions on these facts. I spent almost 8 years on the National Floor Safety Institute’s ANSI B101 committee, when it was still an ANSI SDO and I found one operating principle to be unequivocally true, Russ Kendzior was a dominating force.)

It is important to consider the advantage of each of these organizations and what that says about the players in this field. Since the 1950s, the TCNA has been a reputable standards developing organization that the industry has relied on, and continues to increase the quality and usefulness of standards in maintaining quality and uniformity but also increasing safety. As technology gets better and people are more aware and there’s more statistics and as culture changes, so do these standards. It can be a moving target that’s hard to hit, but having been involved in the NFSI, the B101 committee, ANSI A108, and numerous ASTM committees, I believe the value is in what standards become consensus and are then adopted and used by the industry. Because of this, A326.3 has recently evolved to make it better and provide clarification of different levels of appropriate use of flooring surfaces and given manufacturers a way to clearly clarify what those specifications are.

ANSI Standards – Thorough and Developed

Recently, ANSI updated A326.3 for DCOF testing. Perhaps one of the most important standards in our industry is the guidelines for what passes for slip resistance when floors are wet or dry. Since 2012, the main specification was that values under 0.42 are generally not considered slip resistant in the tested condition. This was a valuable insight that has sustained the industry for years, but as we all know with floors, there is far more to consider than just a baseline value.

Throughout our industry work, we have learned how to evaluate the nuances of floor types for a more consistent and thorough assessment just as other industry professionals do. But the problem arises when each professional believes their assessment is the true guideline. Thankfully with ANSI’s standard development, there are specific and detailed guidelines to use and rely on that will push past any need for opinionated debate on what is the true value.

The recent addition to A326.3 provides guidance for inspection, but it also requires manufacturers to communicate the intended and acceptable uses of their products very specifically through product use categories.

Below is an excerpt from the ANSI A326.3 standard including its recent additions:

3.0 Specification

3.1 DCOF ≥ 0.42*: Unless otherwise declared by the manufacturer, hard surface flooring materials suitable for level2 interior spaces expected to be walked on when wet with water shall have a measured wet DCOF value of 0.42* or greater. However, hard surface flooring materials with a measured wet DCOF value of 0.42* or greater are not necessarily suitable for all projects.

3.2 DCOF < 0.42*: When tested using SBR testfoot material and SLS solution as per the procedure in this standard, hard surface flooring materials with a measured wet DCOF value of less than 0.42*, unless otherwise declared by the manufacturer, shall only be installed when the surface will be kept dry when walked upon and proper safety procedures will be followed when cleaning the hard surface flooring materials. Hard surface flooring not intended to be walked upon when wet shall have a dry DCOF value of 0.42* or greater when tested per Section 10.0 of this standard.

3.3 Coatings: Hard surface flooring materials which have a coating applied after firing, after fabrication, or after installation of flooring materials onsite shall only be used in areas that can be kept dry, unless otherwise declared by the coating’s manufacturer. If testing data is required after a coating is applied, use the test method specified by the manufacturer, or the dry testing procedure in this standard if no test method is suggested by the manufacturer of the coating.

3.4 Manufacturer-Declared Product Use Classification: Manufacturer shall declare product use classification based on manufacturing parameters, internal quality control criteria, their experience with similar surfaces, and the criteria in this standard for all surfaces classified under Sections 4.1.3, 4.1.4, and 4.1.5, mosaic surfaces, and flooring where surface structure (e.g. three-dimensionally patterned or profiled surfaces) results in misleading DCOF measurements due to test device constraints. Surfaces classified under Section 4.1.2 shall also be permitted to be manufacturer-declared. The manufacturer shall define internal product selection criteria for hard surface flooring. Where product use classification is not based on DCOF developed by this standard.

4.0 Product Use Categories

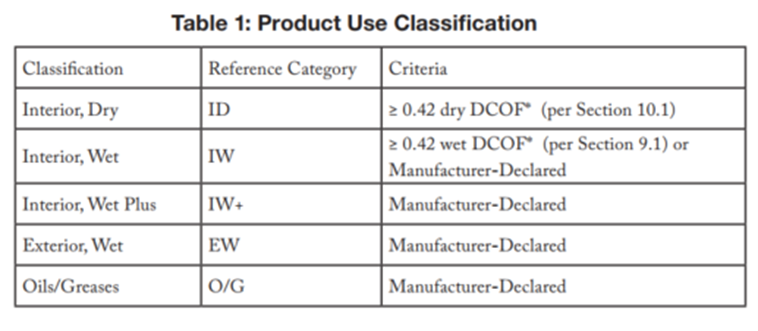

4.1 Product Use Classification: Hard surface flooring products shall be classified into one or more of the product use categories provided in Table 1 and described in Sections 4.1.1 through 4.1.5.

4.1.1 Interior, Dry: Product shall be kept dry, level, and free of contaminants when in use.

4.1.2 Interior, Wet: See Section 3.1. Product shall have a minimum measured wet DCOF value of 0.42* or greater when tested per this standard or be manufacturer-declared for this category based on manufacturing parameters, internal quality control criteria, and manufacturer

experience with similar surfaces (see Section 3.4). Attributes to consider for products

manufacturer-declared for this category include, but are not limited to, product size, texture,

structure, and drainage.

4.1.3 Interior, Wet Plus: See Section 3.4. Product shall be manufacturer-declared for this category based on manufacturing parameters, internal quality control criteria, and manufacturer

experience with similar surfaces. Attributes to consider include, but are not limited to, product

size, texture, structure, and drainage. Products meeting Interior, Wet Plus criteria may require

frequent maintenance to keep clean.

4.1.4 Exterior, Wet: See Section 3.4. Product shall be manufacturer-declared for this category based on manufacturing parameters, internal quality control criteria, and manufacturer experience

with similar surfaces. Attributes to consider include, but are not limited to, product size,

texture, structure, and additionally in wet applications, drainage. Products meeting Exterior,

Wet criteria may require frequent maintenance to keep clean.

4.1.5 Oils/Greases: See Section 3.4. Product shall be manufacturer-declared for this category

where oil, grease, and/or fats may be present, based on manufacturing parameters, internal

quality control criteria, and manufacturer experience with similar surfaces. Attributes to

consider include, but are not limited to, product size, texture, structure, and drainage. Products

meeting Oils/Greases criteria may require frequent maintenance to keep clean.

As testing, materials, and equipment develop, so too should the standards. ASTM and ANSI provide accountability and oversight to ensure that consensus is obtained and that the process is not dominated by one entity. If independent organizations are confident that their experience can benefit future standards, then there should be an effort to join with the already established committees so that this development can continue in an accessible and transparent way.

To Trust Committees or Not? That is the Question

The updates to A326.3 are the type of work that increases safety and is now industry consensus. This is not just a few people asserting this belief, this is the industry as a whole saying we are taking active steps to make the industry safer and hold manufacturers accountable to industry standards. Which basically negates the argument made by Kendzior that the industry doesn’t care and that they just don’t want to get sued. The reality of the industry moving forward is that these types of standards and consensus reduce the risk of a slip and fall, make it easier for people to specify, install and maintain flooring appropriate for their application, and limit the potential for exposure to hazards resulting in injury and yes, they will consequently reduce litigation too.

So really, what does this do? It helps everybody. Kendzior’s assertion that he’s the hero and everybody else is the bad guy, is just not true. There are many professionals working behind the scenes to develop strong consensus standards that are adopted by industry and raise the quality, safety, and sustainability of products; there is no one hero but many and we’re not seeking recognition, fame, or glory, we just want a better world that keeps getting better because of the hard work of good people.

Moore Engineering is composed of industry professionals who provide floor testing and walkway safety auditing services. We also provide expert services to litigators for both Plaintiff and Defense clients. We know our standards and trust the industry consensus as we’ve been intimately involved in developing it for almost 15 years. We happily provide complimentary consultations and can be contacted via phone at 856-437-7900 or through the contact form below.

As always, Test Moore, Fail less.

Leave A Comment