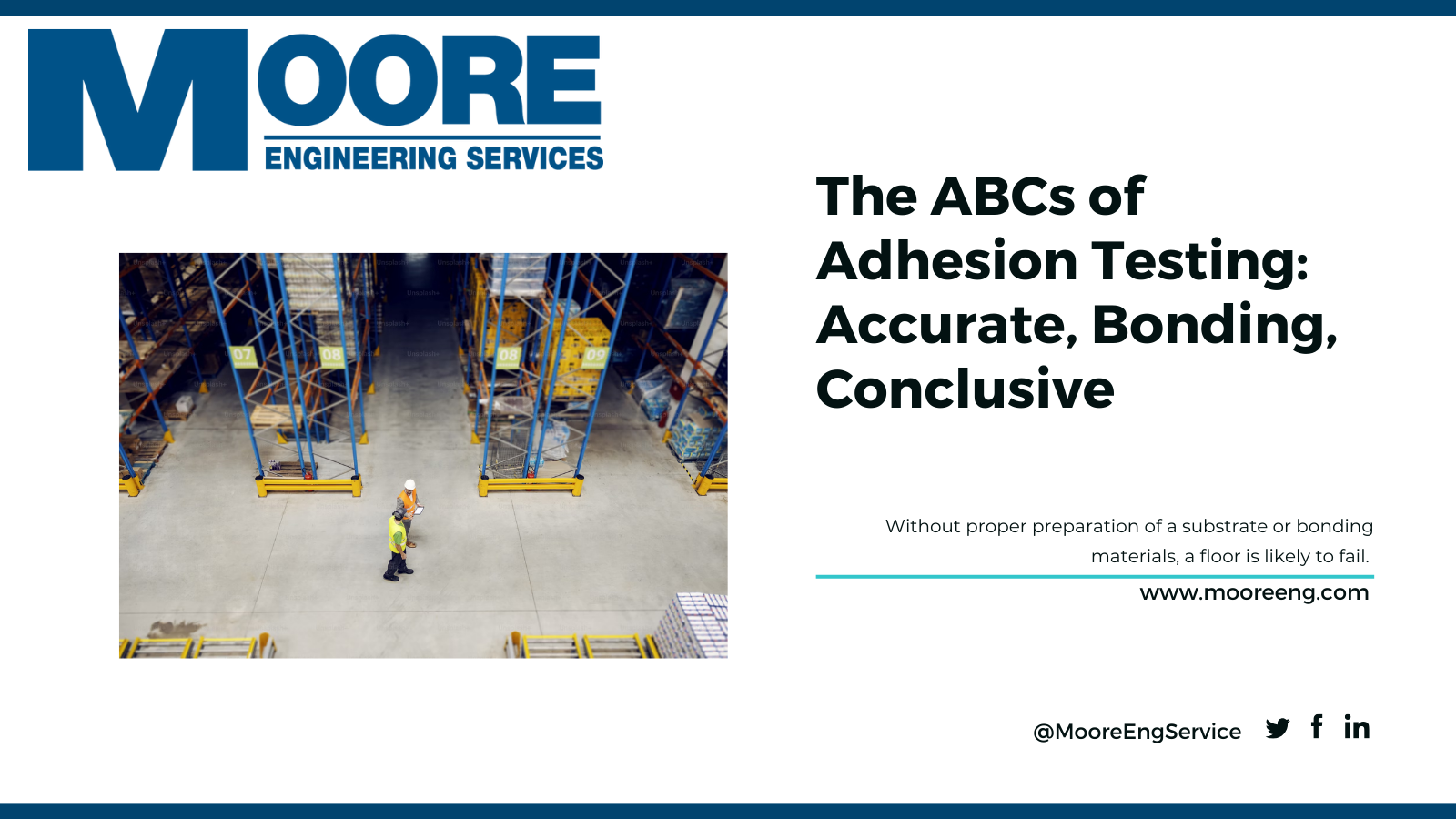

Without proper preparation of a substrate or bonding materials, a floor is likely to fail. The application process and materials vary depending on resinous or resilient flooring, but the preparation process is equally important. Building owners, whether for a retail space, commercial warehouse, or more, will always face constant maintenance issues, and if flooring is one of them then we can help. Industry accepted equipment is used to determine the tensile strength and level of failure of flooring, but it takes a flooring professional to adequately understand where the problem lies.

Testing and Flooring Types

Adhesion testing can be performed on resinous (epoxy, terrazzo, etc.) and resilient (VCT, laminate) flooring; the nature of these two flooring types makes their installation process and the layers involved in applying those floors to vary. Due to the nature of installation of these flooring types, as well as the type of building and age, there are many variables to consider, but there is a common need for the layers involved to be appropriately bonded to the substrate and each other with manufacturer specific instructions for each product dictating how to achieve appropriate bonding. To determine if a substrate can accept a flooring installation or to determine where there may be bonding failures in the layers of different installations, adhesion testing (also called pull-off testing) can be performed by a flooring professional.

Purpose for Testing

Tensile Strength

After scoring the surface, a dolly with epoxy attached to the flooring uses pressure to determine the force at which the dolly breaks away. This determines a strength; usually measured in pounds per square inch, or psi, with the higher the number the more favorable. If the dolly breaks away near the top layers at a low psi then that would be an unfavorable result, whereas if the dolly does not break away until it reaches the substrate at a higher psi then that is more favorable to the bond between the layers/substrate and indicates an appropriate installation quality; however, what is required for specific products is outlined in their manufacturer’s instructions. When testing is done to determine if the substrate is prepared for floor application, the pressure at failure determines if the minimum requirement for the flooring as set by the manufacturer is appropriate to use on the specific substrate. Adhesion testing can be used to determine the tensile strength of concrete substrates in this way.

Failure Rate

We need to understand more than just the tensile strength to have a clear picture of the flooring and any issues. Resinous flooring often has many layers, but due to age and ownership, it is often unknown until testing commences how many layers exist and what those layers consist of. Leveling materials, moisture barriers, and resinous flooring are all possible layers that could exist for epoxy and terrazzo installations. Whereas the pull-test with the dolly determines the tensile strength, the layer at which the dolly breaks away indicates where the bond is the weakest. As flooring professionals, we’re able to visually inspect this point of failure to understand what the layer is composed of and what this means relative to the installation.

Installation Quality

Understanding the failure and where it occurs allows us to determine the installation quality of the substrate and flooring and the weakest link in the system. There are many reasons why flooring fails; indication of this failure is often noticed visually, but the reason won’t be revealed until testing occurs. Testing can reveal if the substrate was not prepared properly for bonding, as well as a variety of other issues that can arise with inadequate application of the other layers. Understanding the tensile strength and where the failure occurs, as well as a visual inspection by a flooring professional, is the practical way to have a clear picture of the installation quality.

Call Us Today!

Our experience has covered the measurement of various materials, from standard epoxy or terrazzo flooring as well as VCT, laminate, and more. Our testing and consultation services save you headaches and loss of money in the future by finding the source of the issue or mitigating future problems. Contact us for a complimentary specification review via phone at 856-437-7900 or through the contact form below.

As always, Test Moore, Fail Less.

Example

Pull-Off Testing

Leave A Comment