We got into this because our clients are regularly trying to both capture and represent dimensional facts. Photographs do a great job, as does drone video, but the best way to show something accurate and to scale is to use a 3D model. The ability to scan objects in the field offers 3D printing applications to other areas of our business which has led us to some very exciting projects.

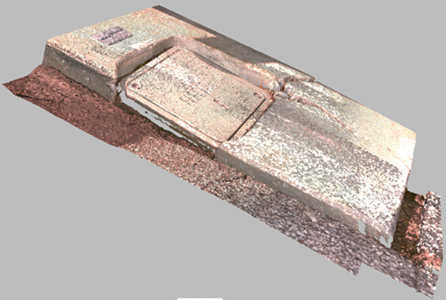

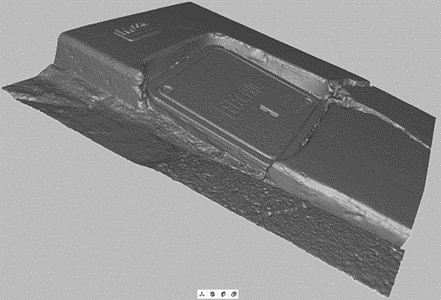

There is a great benefit in representing structural defects for litigation needs. Take a cracked sidewalk; a photo can represent the hazard, but providing a full scale model to a jury emphasizes the hazard even more. Beyond our litigation services, we work with clients on custom projects prototyping products and devices. We believe in the power of serving small businesses and individual client needs.

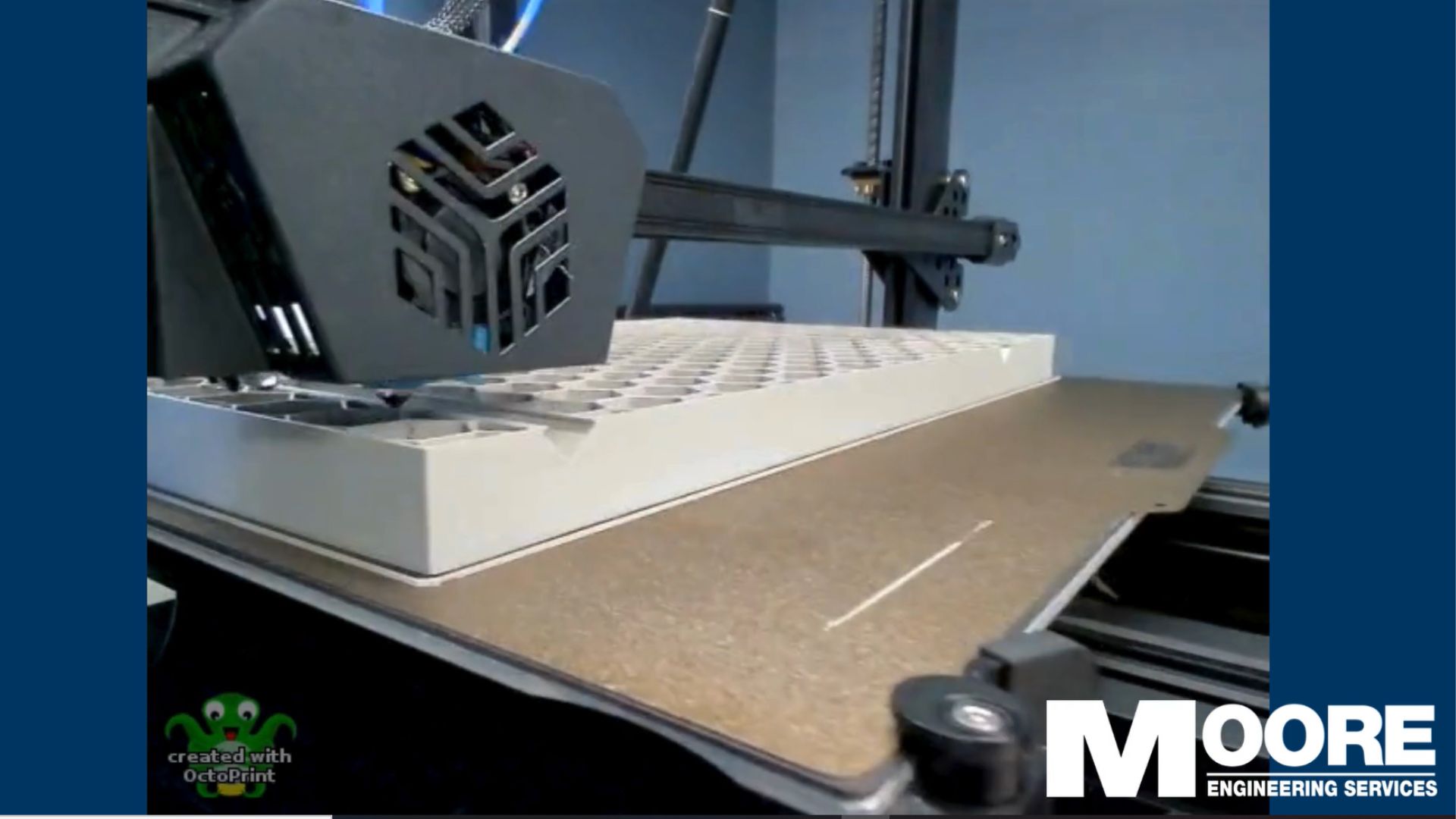

We use Creality CR6 Max printers and print with PLA and PTFE. Due to the number of hours it takes to create a full scale print, we have adopted a technique of breaking the scan down across multiple printers to speed up print time.

The process to create a 3D replicated model of a defect or other structural component is straightforward, but requires dedicated technicians to get the job done right.

For inquiries, please contact us through the form below or call us at 856-437-7900.

3D Scanning Applications

Through our state-of-the-art Artec Leo scanner, we have the capability to scan almost anything and produce a digital file. From the size of a penny to a car, we can scan. Say you need custom measurements for a DIY project, or want a digitized prototype, or even want to make scaled up or scaled down replicas of something important to you, we can deliver.

Already have a 3D printer, but not a scanner? We can scan whatever you need and give you the digital file.

Don’t want a physical print? We can provide the digital file, which you can use to print yourself if you have the capability, or use the scan for your needs.

Custom Design & Printing

With a 3D scanner and multiple printers at our disposal, we can take precise measurements that we utilize in our software to design products to fit the exact measurements and needs of your project.

For car customization, we can design custom integration for a seamless look that highlights new additions. For instance, we designed a component for custom speaker integration in the Ford F150 to perfectly house the new device. Our process works for a variety of car customizations, as well as replacing broken parts.

Our custom work doesn’t stop at automotive. We created additions for tools, such as custom vacuum hose nozzles, as well as custom storage components for easy travel. If you have a unique need or idea, we can work with you to create it, even if it involves creating a product from the ground up using our software.

Scene Capture & Forensic Work

If you need a scanning expert, we have the technical knowledge to scan what you need and send you a perfected digital file. This includes scanning a physical defect, a tripping hazard, an accident scene, or even a car.

Promotional Swag

Desk organizers, custom cupholders, and pen holders are great, but we can make them better through our custom design and printing services to include your company’s logo!

Lead 3D Printing Technician

Matthew Idler has over 10,000 hours of 3D print time and is proficient in using the Artec Leo scanner and its accompanying software, as well as Fusion, Blender, and slicing software. He is skilled in scanning all types of objects and conditions and can troubleshoot problems for thorough scans so he can design and implement the digital files for streamlined printing.

Contact us via the form below or at 856-437-7900 for your 3D Scanning and Printing needs!

MOORE QUOTES

Moore Engineering continues to help our company reduce costs through their engineering knowledge and expertise.

Scott Moore is undoubtedly one of the most serious, honest, and knowledgeable people in the business.

Moore Engineering provided reliable and accurate results in a professional manner, at an affordable price.