I hate moisture testing because it is a twelve-minute problem during every project. The spec page is only open for twelve minutes and unless someone asks for results, it is often ignored or left for the contractor to do on their own. The process is not particularly complicated, but it also isn’t mindlessly simple either. There are a multitude of factors that are all equally important to understand; like the ambient conditions on site, thickness of the concrete, presence of a vapor retarder, whether there are trenches completed with said vapor retarders, and what kind of concrete was used. Even then, you need to understand the requirements of the manufacturers involved, which could be the adhesive and flooring manufacturer and how they are both compatible and both have their own specific requirements. One may require Calcium Chloride testing (ASTM F1869), the other may require RH Probe testing (ASTM F2170, ASTM F710). Understanding why and what you need to do to make the testing is completed properly and provides value and that your floors don’t fail is incredibly important, but just as easy to mess up.

What Could Go Wrong?

The frequency of testing is often something that is overlooked. A lot of contractors just do one or two tests on a 10,000 sq ft job when you should be doing at least 12 to 15 tests on that large of a job. But, honestly, conducting the test is not that difficult. If you have had a situation where you’ve had a floor fail because of moisture, you know the frustration from relying on someone else who didn’t test properly or disregarded the test all together and now you have an absolute mess. Taking too few tests can result in an incomplete understanding of the moisture condition of the entire slab increasing the risk of localized failures in untested areas. Additionally, the manufacturer is not going to warranty it, which means it is up to you to shell out the costs for the material and the labor to make it right. It is also important to remember that most manufacturers warranties only cover the material. If there is a material failure, even if they do cover it, they are not covering the labor or any other cost relative to the flooring failure. That is why the manufacturers require moisture testing for the warranty to be valid. Therefore: it is important to do moisture testing.

After Testing

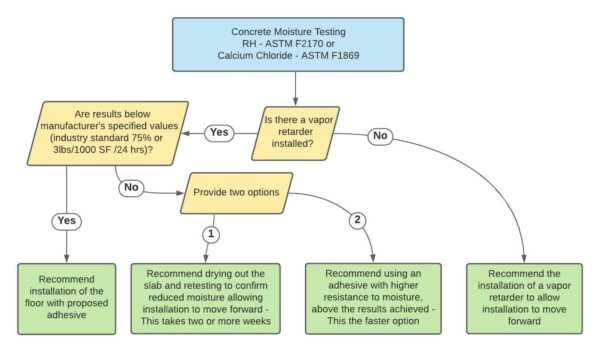

So, what did the results mean? Without any other information, generally 75% relative humidity within the slab is a normal threshold (3lbs/1000SF/24 hrs. for Calcium Chloride testing). Most manufacturers of adhesives will provide what the adhesives maximum threshold is. The same is true with flooring governance. You can specifically get products that have a higher tolerance to moisture in a situation where there are elevated moisture levels.

With high moisture, what do you do? Well, if you have a vapor retarder installed and you have high moisture, you have a couple of options. One is quicker than the other, but more expensive. The quickest fix is to get an adhesive with a higher threshold of relative humidity. The cheaper but lengthier process is to dry out the slab. Without a vapor retarder installed under the slab, the concrete moisture is prone to change with varied ground and outside ambient conditions typically associated with weather and seasonal transitions.

Concrete Moisture Decision Matrix

This can be done by making sure the HVAC is turned on and the space is at design temperature and humidity; usually, 72°F and 50% relative humidity. If you lower the relative humidity in the space, you will pull more moisture out of the slab. This can also be accelerated with supplemental HVAC to draw more moisture out of the space and the concrete, thereby lowering the relative humidity of the air within the concrete. Remember that what we’re measuring here is the relative humidity of the air within the concrete, which is temperature sensitive. Which is why it is important to make sure there is no condensation in the test hole or on the sensors, and that the sensor is properly acclimated before results are taken. It is wise to monitor ambient conditions during testing, usually using a datalogging hygrometer, to avoid large swings in temperature that can cause condensation and errantly high RH readings.

If conducting or overseeing concrete moisture testing using RH probes, here are a few of the basic requirements imperative to its accurate execution:

• Only complete testing when the HVAC is operational and has been running at design temperature for at least 48 hours

• Provide at least 3 tests for the first 1,000 SF and 1 test for every 1,000 SF thereafter with 1 additional test at each exterior wall (most commonly ignored requirement)

• Hole depth should be 40% of slab thickness for slabs on grade and 20% for elevated slabs (measured to the top of SIP forms)

• Allow the drilled and sealed hole to stand for 24 hours before taking measurements

• Allow the sensor to acclimate for at least 1 hour prior to taking measurements

• Be sure the holes remain covered for the entire 24 hours

• Consider monitoring ambient conditions during testing using a datalogging hygrometer

I Hate Concrete Moisture Testing, But…

You may be asking yourself, with all these complexities, who should do the testing? Most testing completed by general contractors and contractors are what causes problems because they aren’t done properly. Like with most things in construction, it makes more sense to have someone who specializes in the area to do the work. For example, having an inspection company that is familiar with testing and has properly calibrated equipment to perform the testing makes a lot of sense.

Don’t Let One Spec Page Bring Your Project to a Halt, Just Do the Dang Testing!

We have extensive experience performing concrete moisture tests covering numerous types of buildings and areas and are prepared to identify and mitigate any issues that may complicate the results of testing. Moore Engineering wants your project to succeed. Whether you hire us or not, don’t ever hesitate to send us specs or results of testing for a free spec review and ask what needs to be done or to ensure the test was done properly. Please contact us via phone at 856-437-7900 or through the contact form below so that we can help reduce the pain of concrete moisture testing.

As always, Test Moore, Fail Less.

Leave A Comment