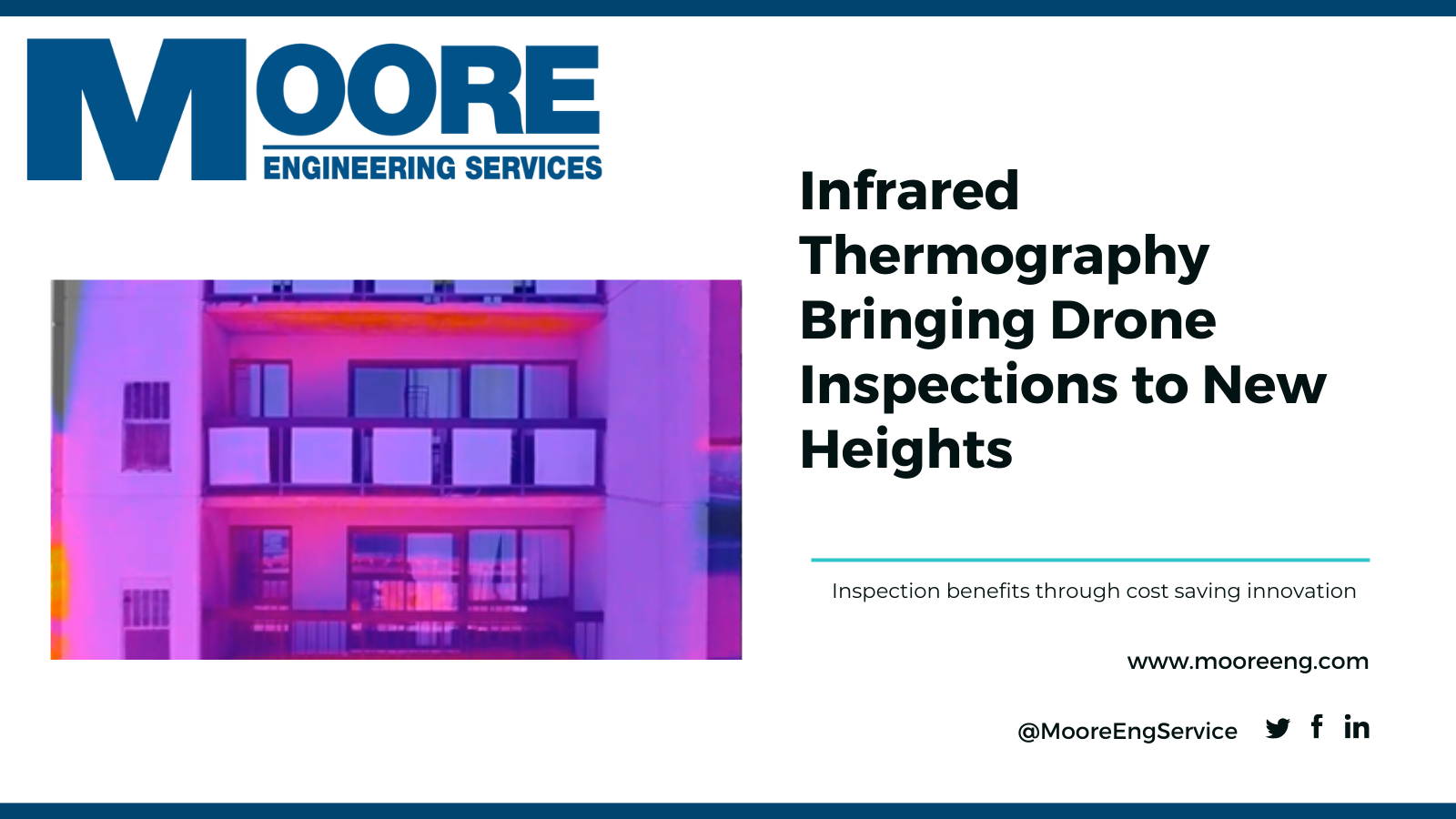

Infrared thermography may sound like something out of science fiction, but its uses are more grounded in common construction and utility services than you may think. Discovered in the 1800s, infrared imaging essentially is the visualization of temperatures releasing energy at different rates. Any object emits thermal energy. Gaining this knowledge has been imperative to common maintenance of utility and construction structures. Many inspections, whether for maintenance, construction, or even residential means utilizing infrared imaging to identify areas where energy (i.e., heat) is escaping, but these services can only go so far with a handheld device. What if I told you we could expand these services to new heights with drone infrared thermography?

Insightful Inspections

Infrared inspections allow professionals to identify areas where there may be a defect, such as lack of insulation, air leaks, roof leaks, breaks in hot water pipes, electrical problems, to even construction defaults. Commonly, professionals will use handheld infrared probes, also known as spot infrared thermometers, for HVAC purposes. Necessary to conduct at specific distances, these services are beneficial for smaller areas. But the use of infrared cameras goes much further as infrared thermal-imaging cameras allow image capture across larger areas. Although these services have functioned just fine up to now, human ability puts constraints on productivity and safety. That is until we have combined infrared cameras with drones.

Large infrastructures need frequent inspections just as any other industry. Inspecting roofs, bridges, and construction progress are just some of the large jobs that entail risks to human safety as well as time sensitive delays. Requiring inspectors to halt work and strap in or climb to extreme heights so an inspection can occur are just some of the constraints we are used to. But why should we turn complacent with these constraints when drone technology removes safety risks and time stalls and potentially increases efficiency while reducing cost?

Utilizing drone technology with infrared capabilities streamlines the inspection process while allowing the individuals to stay safe on the ground and continue their work. Drones can fly to any height to assess the extent of the project from an aerial view and complete detailed roof inspections. Instead of taking hours upon hours to evaluate whether thermal energy is escaping from a large structure, a drone can assess the entire structure in one go with an infrared camera to determine any defective areas. Thanks to the compact size of most drones, they can also fly in tight areas that may cause issues for most inspectors. And the best thing is, work does not have to stop while conducting the drone inspection.

Using Infrared Drone Technology for Roof and Façade Inspections

Whether it is an overhang feature, a decaying roof, or part of a construction project that is difficult to access through traditional means, drones can access all these areas in just a fraction of the time and expense a normal inspection would take. Focusing our attention to building envelope inspections has allowed us to perfect the process, thereby allowing for detailed and efficient results to benefit your maintenance or construction needs. When it comes to roofs specifically, there are many reasons why inspections are necessary. Some of them include:

- Identify leaks and defects

- Assess real estate value

- Evaluate repairs necessary to estimate costs

- Confirm insurance claims

- Prepare for solar panel installation

- Routine maintenance

To complete these inspections in the past, personal safety and high costs were put at risk. Quite often inspectors fall and injure themselves or even experience the roof collapsing. In 2019, OSHA reported 5,333 total fatal workplace related injuries with 1,061 of those occurring in the construction sector. According to the American Academy of Orthopedic Surgeons, every year 500,000 people are treated for falls and ladder-related injuries, in which in 2010 work-related falls occurred from roofs or ladders totaled to 646 people. With drones, all those risks disappear. Because we no longer need to worry about the process and preparation of ensuring the laborer is ready and able to mount the roof and complete their inspection, money and time is saved.

Verified Flights

As a licensed drone pilot as well as a licensed engineer, my services entail not just efficient drone flights and video editing, but also the knowledge of the imperative areas and issues necessary for a full inspection. Earning your drone license and managing the complicated Northeast airspace is one thing, but understanding the importance of inspections for matters like roofs and construction projects is something else entirely. When roof and façade imperfections add up, it is very easy for these conditions to fall into disrepair and eventually damage the rest of the building.

My decades of experience as an engineer have benefited me with the practical knowledge of industry standard practice necessary for appropriate building practices, as well as understanding where potential defects may lie. That way, instead of having to worry about what a thermal spike may mean, I am able to track all areas and provide you with an appropriate assessment of the infrared data. We also work with industry experts, like ARMM Associates, to provide these services and the valuable interpretation of the results.

Please contact us via phone at 856-437-7900 or through the contact form below about how my full-service drone inspections may benefit your construction or maintenance needs. Fully insured and equipped to plan and manage the airspace in compliance with FAA Part 107, Moore Engineering Services can provide drone inspections for all your needs.

As always, Test Moore, Fail Less.

Infrared technology will revolutionize the drone industry. That’s why drone inspection technology will get better and more precise to be used by multiple industries.

Hey, g’day there! It’s so amazing to discover that even infrared drones can be used to determine what kind of solar panel configuration should we go for. My cousin lives in an apartment building and he’s been considering relying on solar power to provide electrical supply for his place. I’m so gonna show this article to him so he could use the right equipment to further examine the entire situation later on.